Most of the time companies do not opt for the plastic injection molding method and they choose the other expensive methods. However, this is one of the best methods of manufacturing the final product be it of aerospace parts, automotive parts, or medical equipment parts. During its production, many companies choose to use aluminum molds. There are traditional methods where the manufacturing companies use steel, but that’s an old method. But it’s high time that the manufacturing company should see the merits of using an aluminum mold. The first and foremost benefit of aluminum mold is that it is cost-saving. Next, a benefit that you get is that you get a more improved manufacturing cycle which can keep more than a hundred different types of thermoplastic resins.

Different Injection Molding Services –

Apart from that, there are two different types of services that you will get in plastic injection molding. One type of service is on-demand manufacturing and the other is high production manufacturing i.e. prototyping. So, which type of service your company chooses with the manufacturing firm totally depends on the need of your production or production need or project. Plus, each one of them has its own benefit. But there is one thing, prototyping kind of services can become critical at a times. Manufacturing that is on-demand is the best one as suggested by the manufacturing firms. Plus, it is a cost-saving type of service compared to prototyping.

What happens in Prototyping?

Basically, what happens in prototyping is that the parts/pieces that are needed to be molded if they are in large quantities then the manufacturer will look into the cost of each piece or part, and these will need rapid production which at times becomes critical. As mentioned above prototyping kind of services of manufacturing can become critical at a times therefore, manufacturing companies mostly feel that on-demand manufacturing is the best type of service that they can offer. Now, most of the time companies will have a question that why should they choose plastic injection molding when other methods are also there? Or why should they choose the ideal or best service method?

Reasons for choosing this molding method –

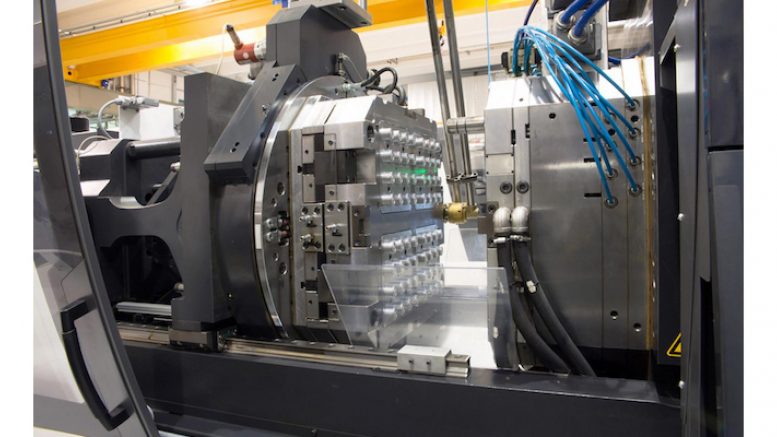

The reason why your company should choose a plastic injection method is that in this method the molding is done through the injection which is a highly technical process that influences manufacturing mechanization. Afterward, the parts or pieces are sent to the production area where the milling process begins of the molds. As already mentioned the molds that are used are made of aluminum. This aluminum mold is a cost-saving tool and is best compared to traditional steel. Plastic injection molding methods are the easiest one as the plastic pellets are melted and once it comes in a good liquid state then they are injected through pressure at the opening of the mold, which comes in the shapes and sizes in accordance. The colorant is sometimes added to the liquid plastic.

Advantages –

There are several advantages of this method and some of the benefits are that when the product finally comes out, it is the most consistent product. In some production companies, the cost per part is also lowered if there are orders in bulk, but again that is critical and in some companies, the cost per part is not reduced. So, check with the production companies to know more. A complex part with geometry is manufactured very smoothly.