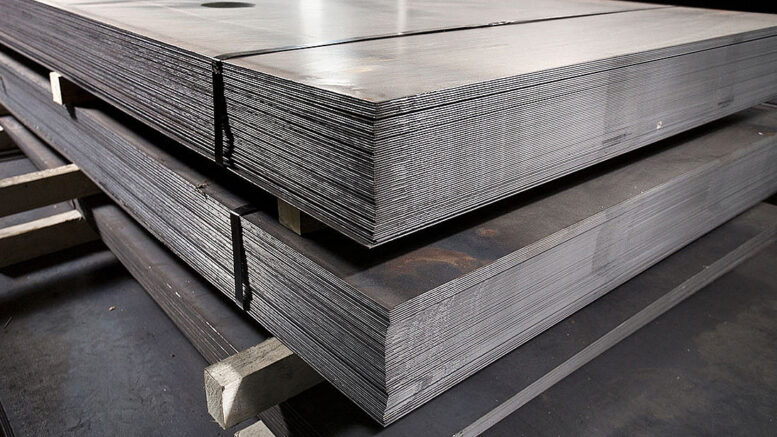

Sheet metal is one of those shapes and structures that can be purchased in metal. Sheet metal is any metal whose thickness is between 0.5 to 6 millimetres. The sheet metal will be shaped like a mechanical circle in a single, tapered, level piece. Sheet metal is one of the important structures used in metals and can be very well cut and bent into an assortment of shapes. Slender sheet metal is probably the most regularly used material of all, through development. In fact, it is used in countless different undertakings like this, and it is the most conceived development material on the planet.

What is the need for you to use sheet metal?

Sheet metal is with a whole host of advantages. The first is that it is so natural to ship this material. Sheet metal is lightweight and can be stacked advantageously. This implies that transporting is not a problem, even in huge quantities. Sheet metal is likewise very climate-safe, because of the material that is arranged after its manufacture. This synthetic system assists with forest harvesting and even UV barrier.

Additionally, the meaning of sheet metal is surprisingly solid. Truth be told, many mortgage holders pick up the metal material immediately after their strength. The most commonly purchased metals include aluminium sheets and hardened steel. In sheet structure, these metals have a whole host of good planets.

What are some of the most common types of Sheet metals?

There is a wide range of metals and compounds that come in sheet structure and are eventually used in the fabrication of fabricated parts. The decision of which material generally depends on the end-use of the manufactured parts includes durability, weldability, erosion blockage, strength, weight, and cost. Accuracy Most basic materials found in sheet metal fabrication include:

- Stainless Steel

- Cold-rolled steel

- Pre-plated steel

- Aluminium

- Copper brass

What is the process of using sheet metals simply?

Sheet metal can be cut, stepped, framed, punched, bent, bent, rolled, rolled, pierced, Can be taped. The device can then be embedded to fix electronic segments, metal sections, or various bits of sheet metal. To complete sheet metal, it can be very well brushed, plated, anodized, and powder-covered, fluid painted, silkscreen, laser-scratched, and cushion printed. What’s more, parts can be bolted to complex functions. Selection of a material, for this situation, sheet metal is the initial stage in the negotiation of any scheme. The conversation starts with the ability of the part you are proposing to plan.

The capacity of the part will help in deciding the required plan. Choosing materials and measurements is a basic progression that involves adjusting factors such as strength, weight, and cost. It is anything but a basic cycle yet can be smooth using the CAD model with the best scheme contemplation found in the white paper. The following actual test, nevertheless, is the prototype. When selecting construction providers, search for organizations with a demonstrated history in delivering parts and bring in abundant amounts of construction information to guarantee fewer hiccups in the planning of the construction cycle and make items appear faster Is brought to.